MCM Panel Systems

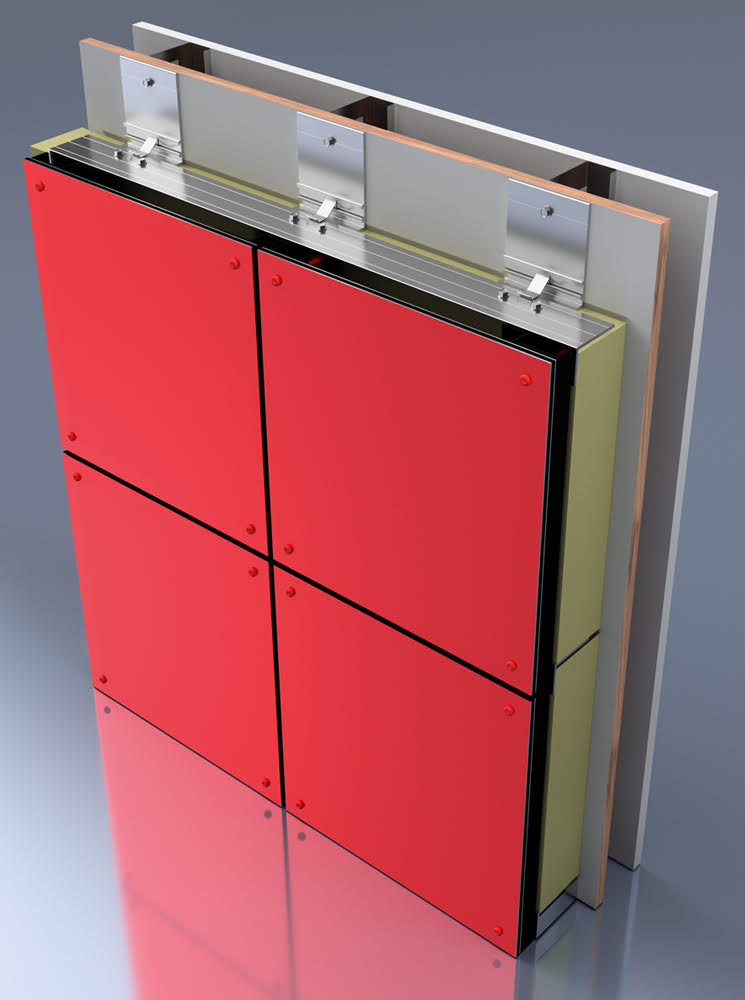

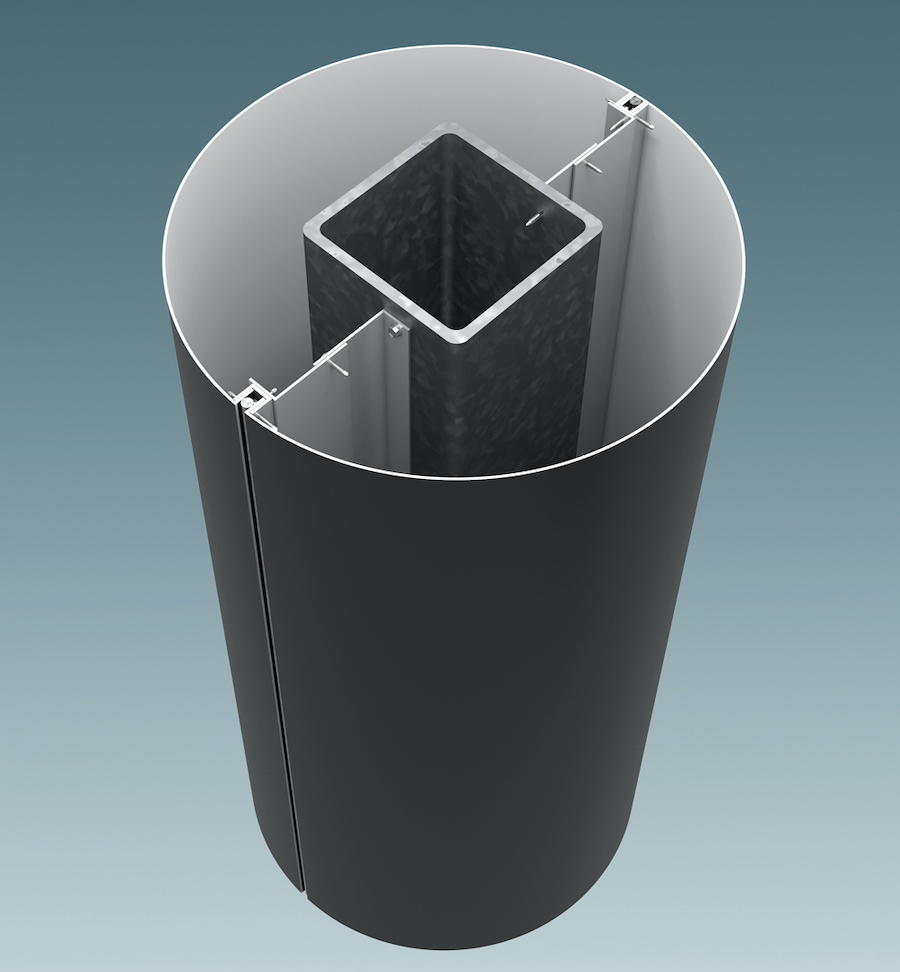

MCM — short for metal composite material — is corrosion-resistant, distinctively colorful, and lightweight yet rigid panel. The use of aluminum plate in MCM Panel Systems achieves a painted surface and is compatible with other natural metals, ensuring reinforced, weather-resistant exteriors. MCM Panel Systems are easy to install, providing strength and durability at a competitive price. By utilizing CEI Materials Rainscreens and Route & Return Wet Joint Systems, our clients are able to broaden their architectural horizons.

Read on below, view our project portfolio for examples, or request a quote now.

.png)