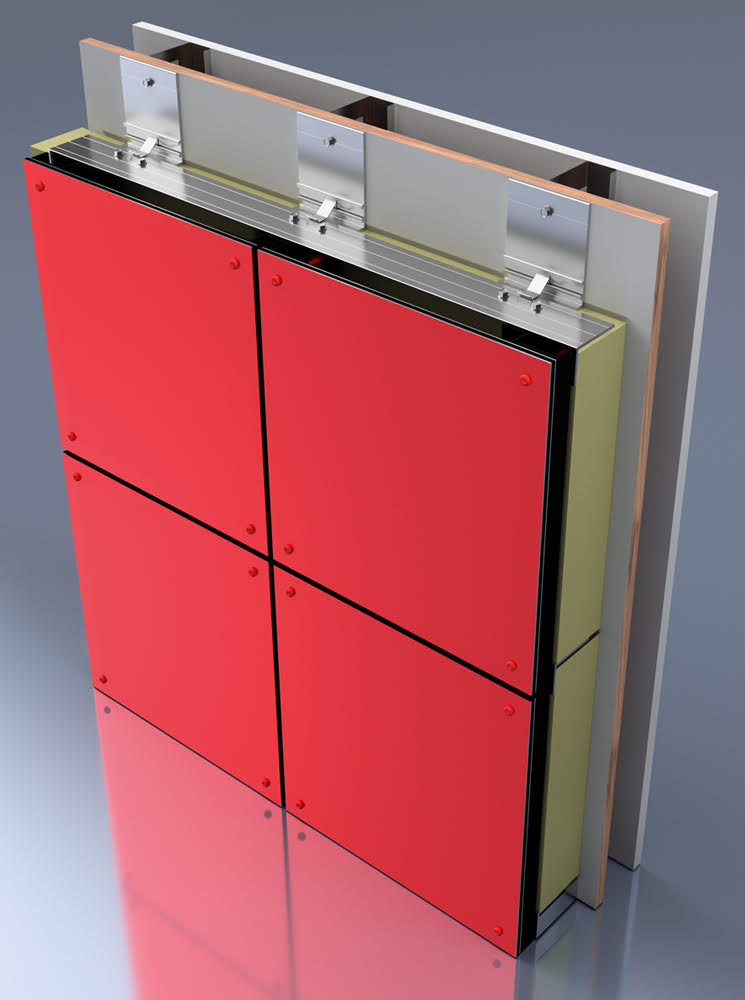

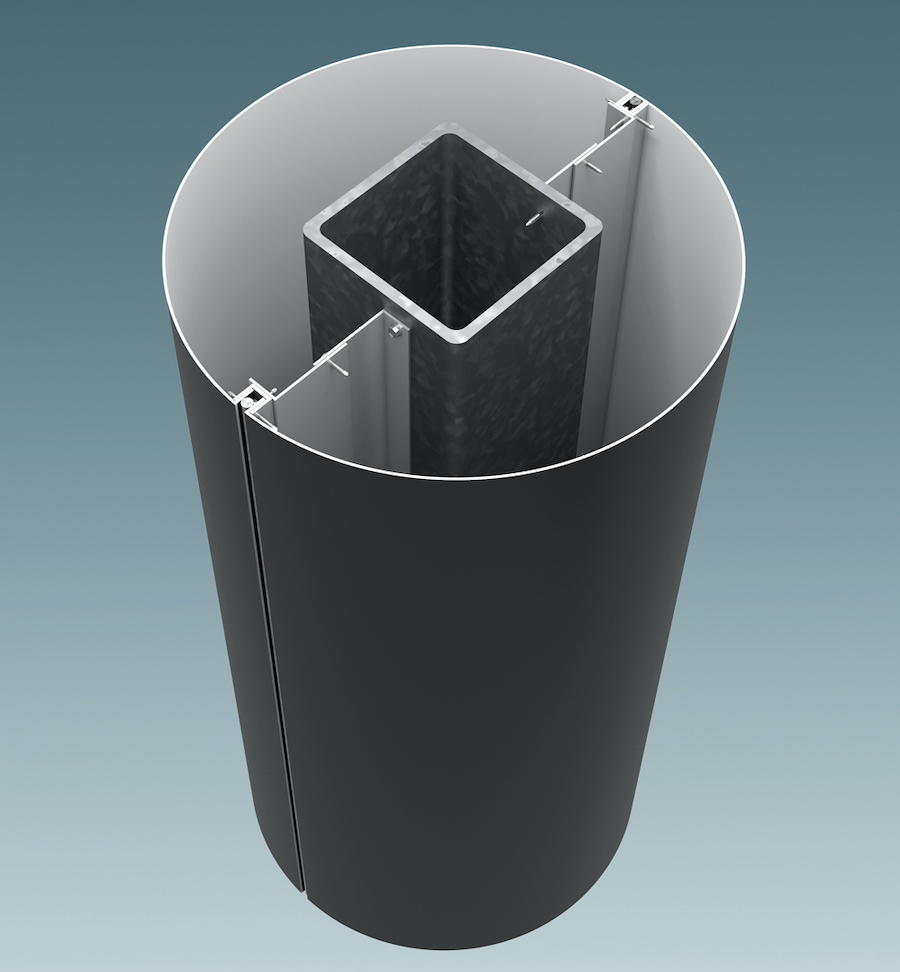

Aluminum Plate Panel Systems

Aluminum cladding panels offer the flatness and stiffness of MCM panels but with the durability, weather resistance, dent resistance, and recyclability of sheet metal. Aluminum plate panels are available in conjunction with the following CEI Materials attachment systems: R3000, R4000, W5000, E1000, CL100, CL200, CL300

.png)