.jpeg)

CEI Materials Can Seamlessly Integrate 3D Laser Scans into BIM Models for the Prompt and Accurate Execution of As-Built Drawings for Production

Architectural software has evolved far beyond vectorized 2D and even complex 3D models on a computer. Competitive practices employ Building Information Modeling (BIM) by imbuing the graphical objects with metadata that dynamically responds to user input.

A sufficiently advanced software is able to automate:

- Dimensions

- Project information

- Schedules

- Cut planes

- Graphical representation

- View references

Our utilization of the most sophisticated software (AutoCAD®, Inventor® and Revit) allows us to seamlessly integrate 3D Laser scans with architectural renderings for the prompt execution and submission of shop and production drawings.

Software solutions should be capable of:

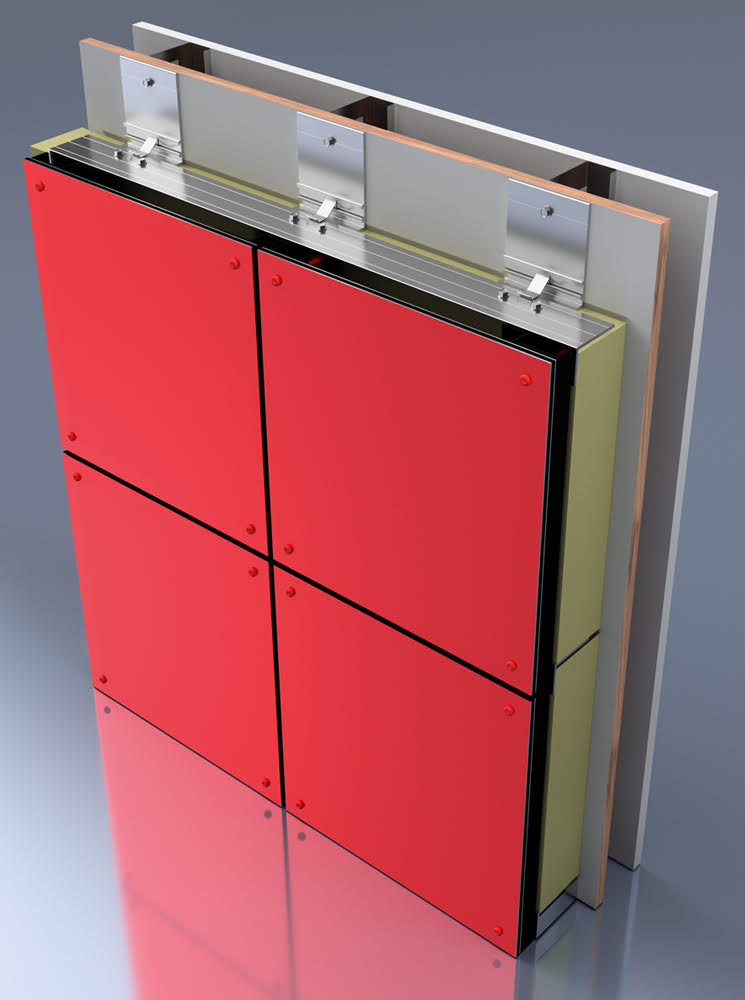

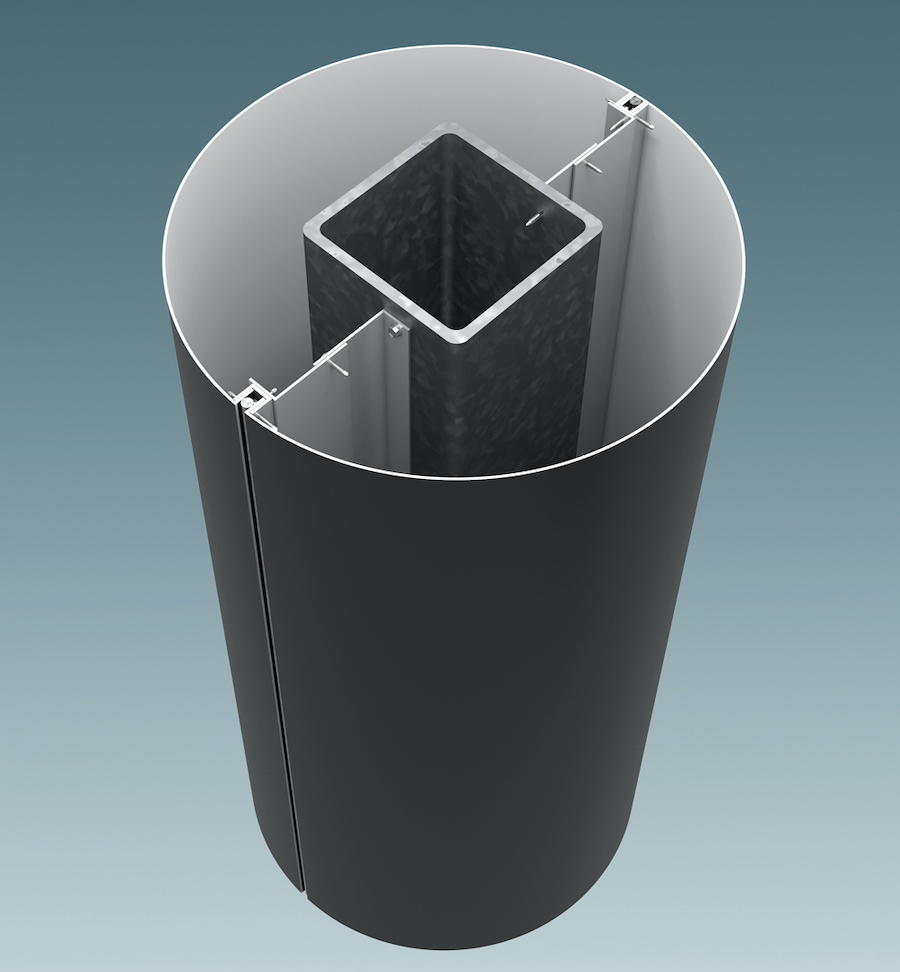

- Producing system-specific 3D panels to specifications based on 2D surfaces

- Layering panel-specific complex information (color, orientation, material, etc.)

- Automatically produce hardware takeoff schedules

- Adjust panel requirements to match building code

- Create and place drafting views onto sheets for each unique panel type

- Compile format-friendly exports to be used in fabrication and other departments

.png)