The Modern Fabricator and The Changing Nature of the Key Players of Architectural Panel Systems

CEI Materials has invested heavily in the areas of design, technology, and robotic production capabilities in order to become a modern fabricator and better serve its AEC customers. Over the next several months we are going to spotlight the meaning of the modern fabricator and how CEI Materials has adapted and developed internal processes in order to meet market demands.

Over the last several years architects have seen a number of changes that affect their design process. The design process is now far more complex with the evolution of cladding materials, advancements in BIM Modeling and 3D Laser Scanning capabilities, changes in building and fire codes, and a movement towards more sustainable and energy efficient design.

The architect now requires a solution-driven partner who can be on the same technological level and have the knowledge base/understanding of different surfaces and attachment systems. The architect desires a partner who understands the entire design process and can help achieve their vision. To meet these needs, the “modern fabricator” was established.

Historically fabricators were largely seen as facilitators, whose primary responsibility was to provide an attachment system along with the fabricated predetermined material. The technological capabilities were mainly production focused and they had limited involvement in the design process. Manufacturers were the main driver of his involvement in any given project, they were the primary contact with the architect. While the manufacturer, fabricator, and installer are still the key players in the design, engineering, and fabrication of architectural panel systems but their involvement has changed.

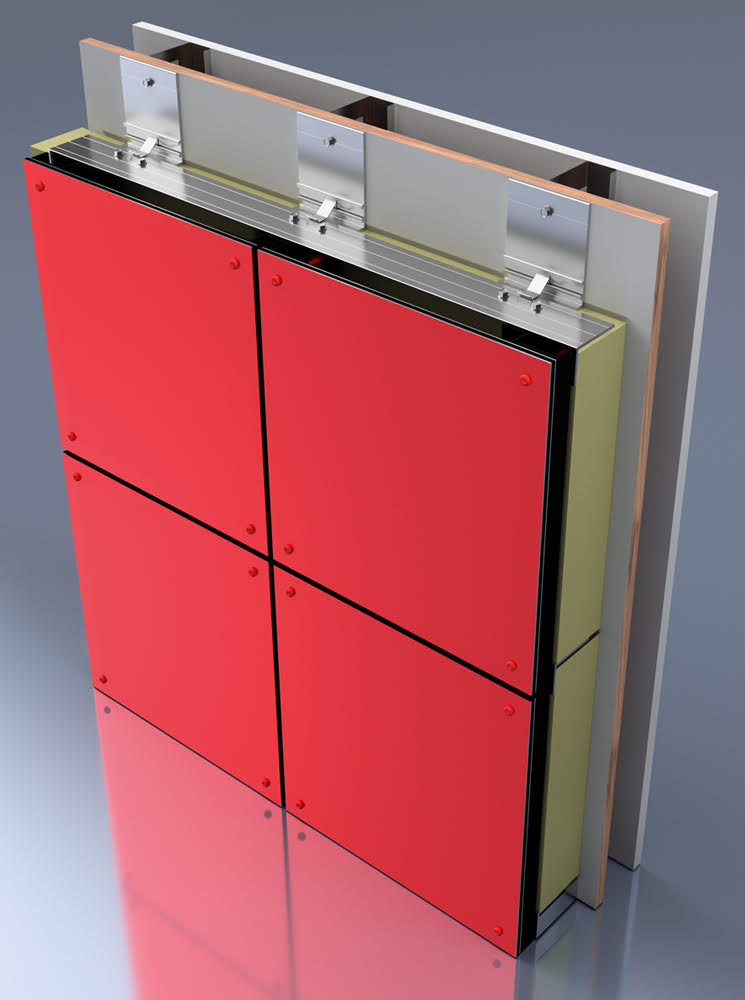

The manufacturer produces a flat sheet product. They initiate testing and certifications of the product and production is continuously conducted to ensure quality in product performance and appearance. While the manufacturer may suggest a compatible attachment system, they rarely provide one. If they do it is a relatively simple in design and single product focused. They do not have the same attachment system knowledge as the fabricator. Their production facilities are located across North America and Europe to provide flexibility in production and the finished product, in terms of quality and appearance, is typically warranted by the manufacturer.

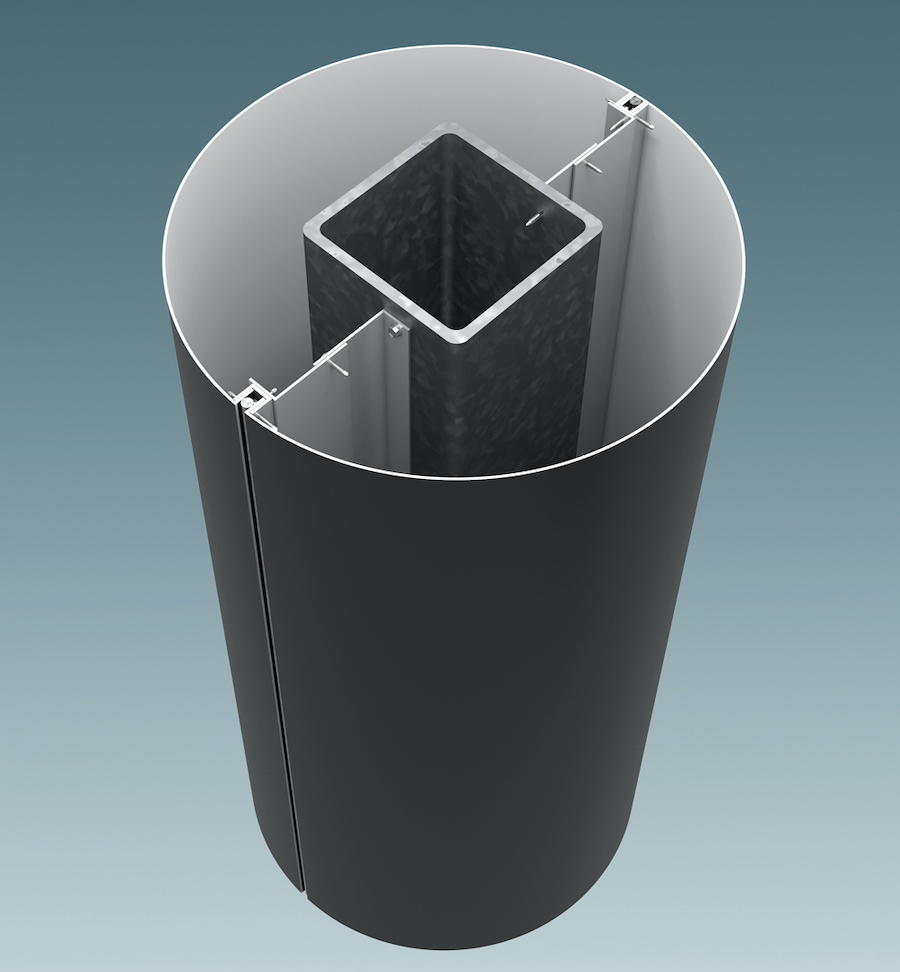

The modern fabricator now plays the most influential role in the design and fabrication process. Additionally, the fabricator is responsible for taking the manufacturer’s flat sheet and producing a functioning architectural panel system. They create the shop drawings and provide engineering calculations showing the accuracy of the panel system design for a given project. Internal testing provides performance parameters for wind, water, and fire for the specification of national and local code requirements.

Furthermore, the fabricator designs, sources, and fabricates the structural components such as Perimeter Extrusion, Attachment Clips, Stiffeners and Fasteners that are required to fabricate sheets into cladding panels. The system is further tested to meet the defined performance requirements in Water Penetration, Structural Performance, and Energy Performance. The architectural panel system, in its entirety, is warranted by the fabricator.

The last crucial role in the process is installation. The installer works closely with the fabricator to coordinate material deliveries to the jobsite. The installer may also coordinate with other trade members for installation of the fabricated cladding system and they provide materials and labor to produce weather tightness of the specified design. When 3D scanning is not viable due to site access, the installer may be required to conduct final field measurements. And while the system is warranted by the fabricator, the workmanship and installation, per the fabricator’s specifications, is warranted by the installer.

Although involved in the design, engineering, and fabrication of architectural panel systems, the manufacturer, fabricator, and installer play vastly different roles. The key players have adapted to meet the growing needs of the AEC community. The process now requires the participants to be more sophisticated in their individual roles. Like architects, fabricators are now required to be solution-centric and need to be multi-faceted in their capabilities, sparking the creation of the modern fabricator.

.png)