The Modern Fabricator: A Vital Partner in Ensuring Compliance with Mandated Testing

In the construction industry, mandated performance testing is a critical factor that demands continuous monitoring and adaptation. With advancements in technology and shifting societal expectations, the pace of change has been extraordinary. Modern fabricators must stay ahead of this evolving landscape, adjusting their products and technologies to meet a variety of testing standards.

Performance testing has become increasingly sophisticated, with numerous building codes in place at both national and local levels. These codes address essential factors such as energy efficiency, fire resistance, structural integrity, and air and water infiltration. All mandated tests must be conducted by accredited third-party organizations, and it’s important to note that testing requirements vary not only between the U.S. and Canada but also by individual states and regions.

While manufacturers are responsible for testing their specific products, fabricators are tasked with documenting and clearly demonstrating what tests and procedures have been performed. This includes internal assessments as well as third-party testing.

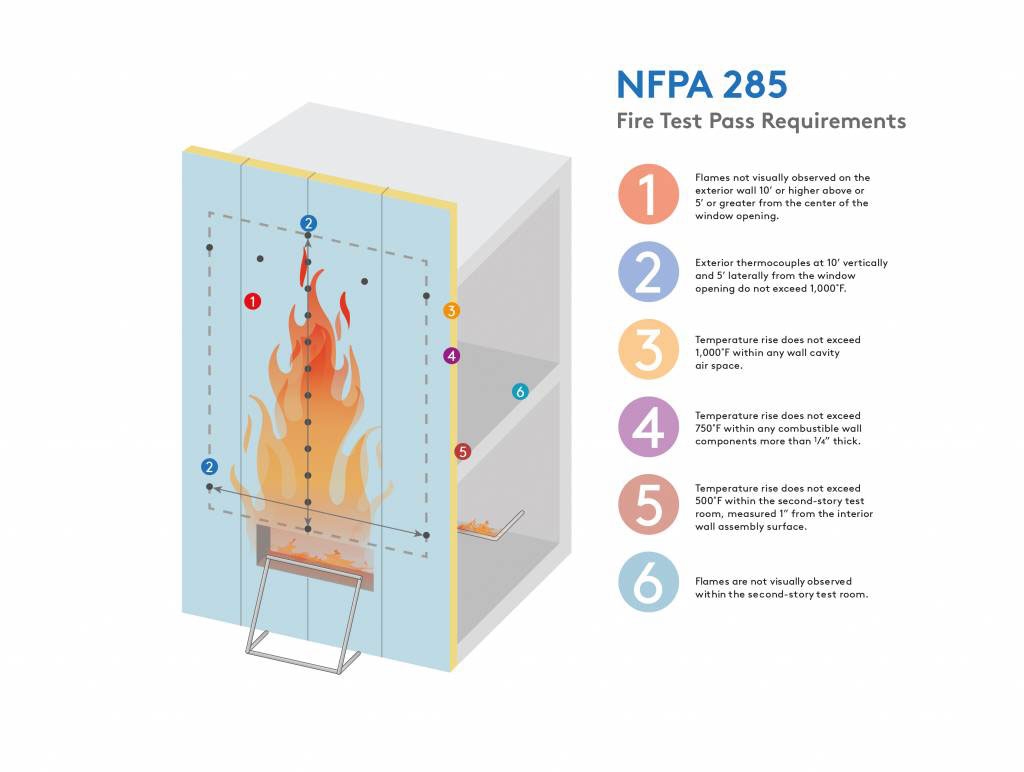

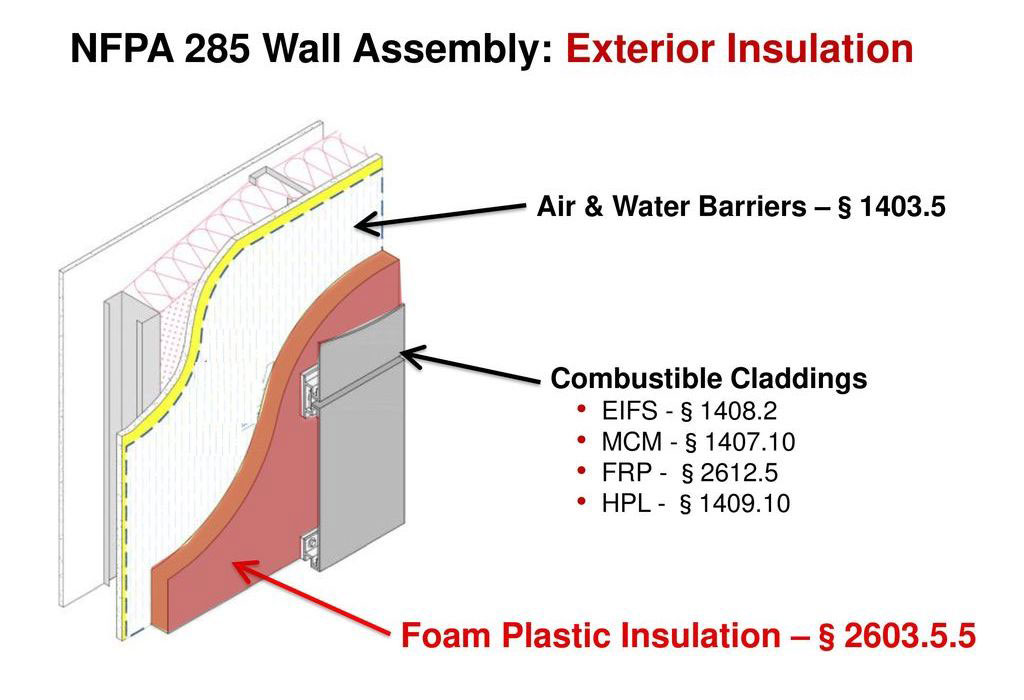

For example, the NFPA 285 standard tests fire propagation characteristics of exterior wall assemblies containing combustible components. At CEI Materials, all systems, except INOVEZE, meet the stringent NFPA 285 requirements set by the International Building Code (IBC) for complete wall assemblies.

When CEI Materials develops a new attachment system, in-house testing is performed before it undergoes third-party evaluation. This process is closely monitored by the business development group, which works in coordination with the special projects and production teams. While building codes may not change frequently, any updates are initiated by governing bodies, and CEI’s business development team ensures compliance with new requirements.

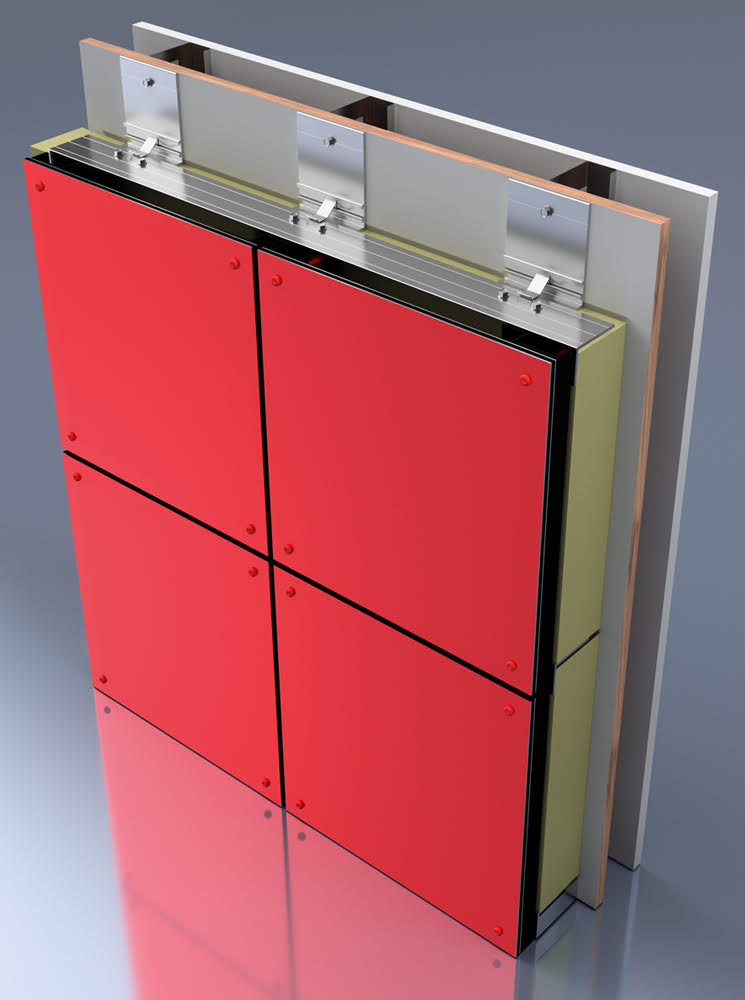

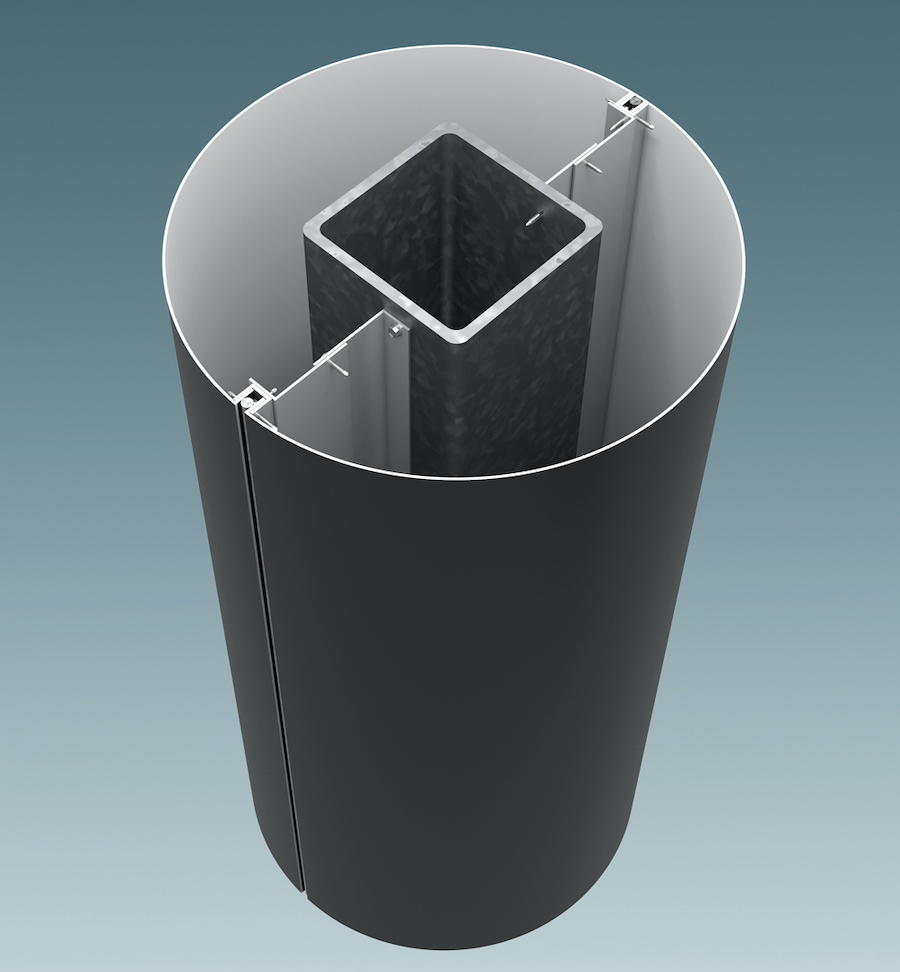

Take the R4000 Rainscreen Attachment System, for example. In the past 13 years, it has been updated twice—once to improve structural performance and again to comply with NFPA 285. Currently, testing is underway to meet the High Velocity Hurricane Zone (HVHZ) Code, a specific requirement in Florida’s Broward and Miami Dade Counties.

For companies like CEI Materials, Florida Approval is mandatory, requiring products to be evaluated by an engineer specializing in Florida Product Approval. Once approved, products undergo unannounced audits annually to maintain certification.

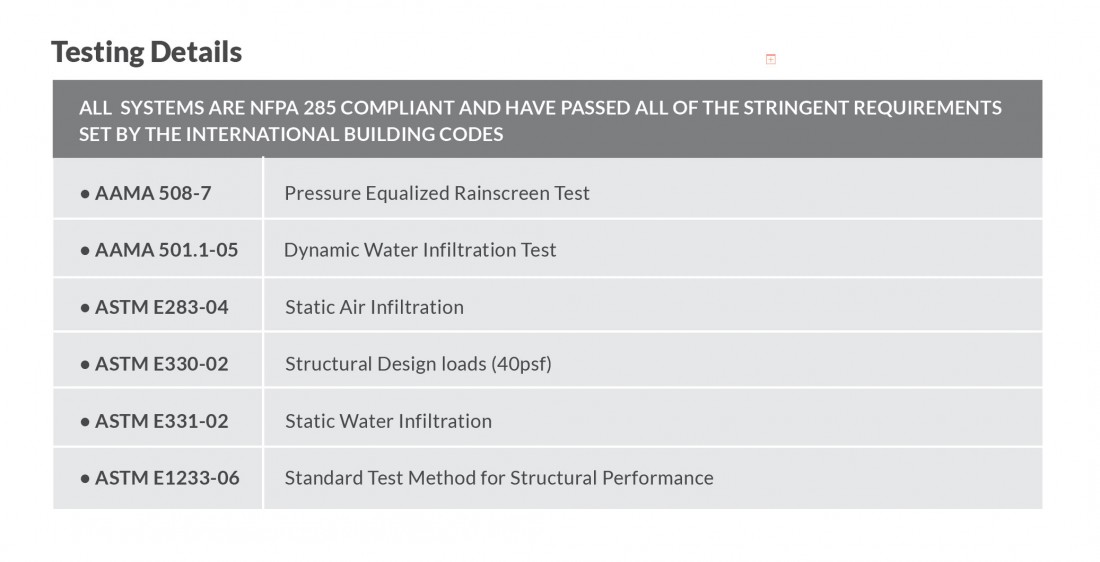

When multiple materials are used in an exterior system, such as a combination of high-pressure laminate (HPL) and metal composite material (MCM), each material is tested individually. Exterior cladding systems typically require a similar set of tests, including ASTM 283, 330, 331, AAMA 501.1, 508, 509, and NFPA 285 for combustible products.

When multiple materials are used in an exterior system, such as a combination of high-pressure laminate (HPL) and metal composite material (MCM), each material is tested individually. Exterior cladding systems typically require a similar set of tests, including ASTM 283, 330, 331, AAMA 501.1, 508, 509, and NFPA 285 for combustible products.

Architects can trust modern fabricators to be their reliable partners throughout the building process. With a fabricator’s deep expertise in testing and compliance, architects can focus on design, confident that their chosen systems have been thoroughly vetted and proven to meet all necessary standards.

NFPA Fire Test Pass: Image courtesy of Construction Specifier

NFPA Wall Assembly: Image courtesy of Dupont

.png)