The First Key Steps In The Modern Fabricator Process: Design Assist, Estimation, and Project Management

For the fabricator to handle the most complex construction challenges, and still deliver the highest quality products, a well thought out and tested process and workflow needs to be in place. At CEI Materials, we have created such a process with personnel that are well-equipped to anticipate and overcome potential design issues that may arise well before any fabrication takes place.

According to a recent report from the AIA, “Design Assist describes the collaboration that goes beyond informal involvement. The goal of Design Assist is to provide contractors an opportunity to suggest modifications to design elements while the design is still being developed. If the contractor can inform the design in a way that will save time or money, or provide some other benefit, it’s better for the design professional to consider that information before construction is underway when changes are costly and time consuming to implement.”

3D Rendering courtesy of Clark Construction

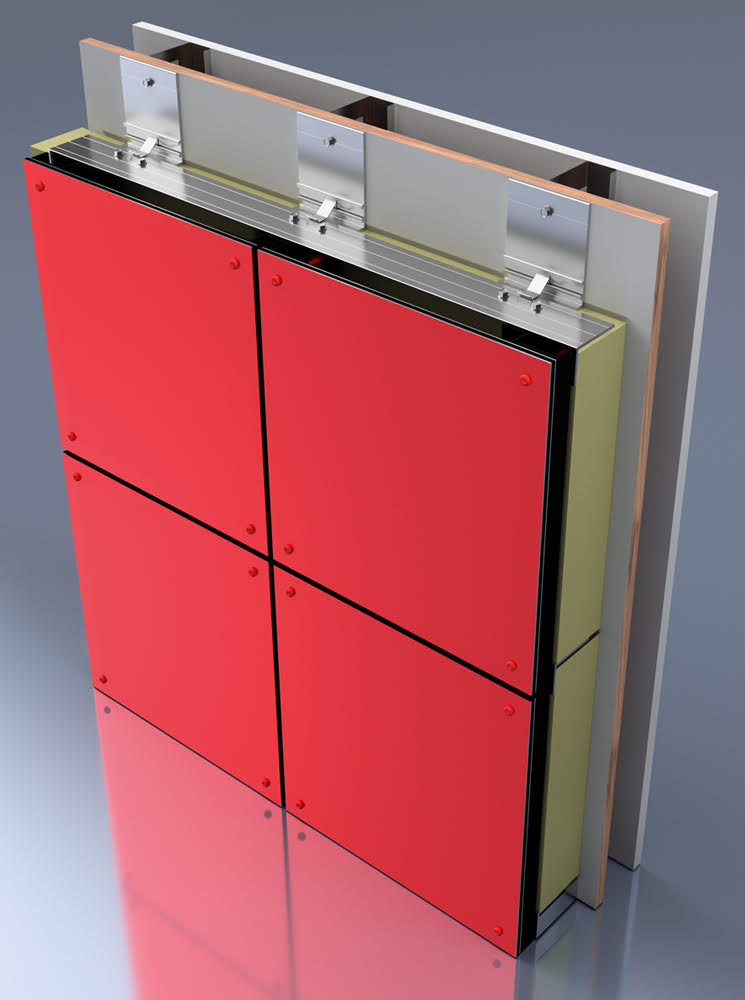

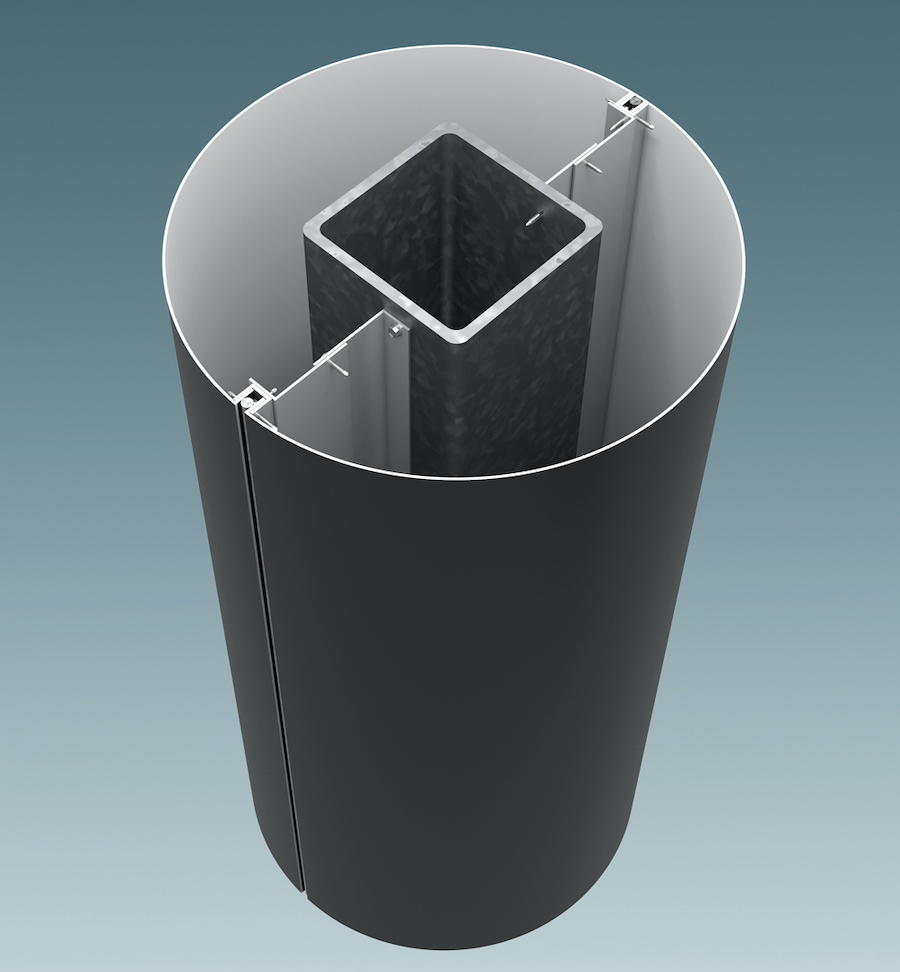

A modern fabricator is a solution-driven partner who can collaborate with the architect and assist in the design process either during the schematic design or the design development phases of the project. As discussed previously, the modern fabricator can advise the architect on how selected products can be attached to the building envelope. Also, they can address such key factors as recommended materials and systems and how they are selected based upon code compliance, cost efficiencies, availability, sustainability, and the total wall assembly.

CEI Materials has the technological understanding and expertise when it comes to the total wall assembly. The internal Design Department has specialty training and capabilities to understand the latest building codes trends and requirements. Working in unison with the Estimating Department to make sure that the following aspects of the project are maximized; clearly written specification, more complete drawings with details, optimized panel layout, and less RFI’s. Additionally, ensuring that the wall construction is designed to fully support the cladding system and eliminate unnecessary sub framing.

Coordinating and controlling the continuing process in transition is Project Management (PM). PM bridges the gap between the fabricator and the client to reduce risk and maximize design efforts. Project managers are experienced and well-resourced to help anticipate potential problems and provide solutions before fabrication commences. Open communication and quality processes enable the PM to significantly reduce production lead times and completion dates while still delivering highest quality products and solutions.

Coming soon to the CEI Materials’ blog: The next phase in the fabricator process, where keeping pace with new hardware and software technologies is key.

.png)