LEED Gold Residential Development Wows Downtown Silver Spring With Fabricated Metal Systems By CEI Materials

| Project Name: | The Pearl |

| Location: | Silver Spring, MD |

| Architect: | Design Collective |

| General Contractor: | Clark Construction Group |

| Installer: | Supreme Metal Solutions |

| CEI Products: | MCM |

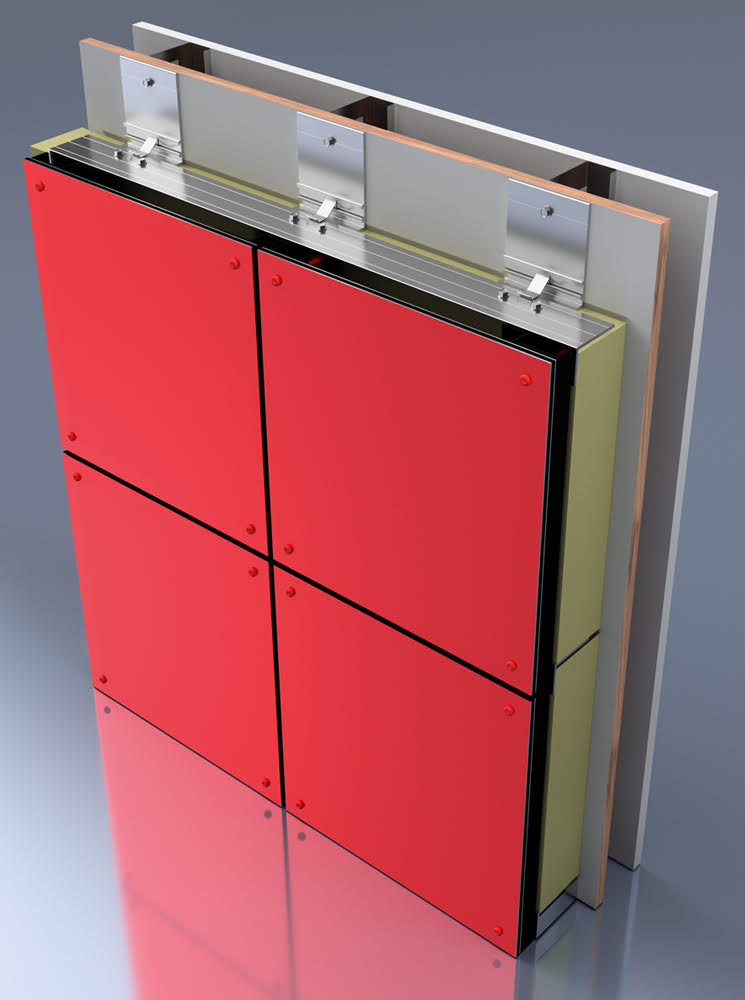

| CEI Materials System: | R4000 |

| LEED: | LEED GOLD |

| Photography: | CEI Materials |

In the massive 27-acre Blairs Development in Downtown Silver Spring, Maryland sits The Pearl, the new residential towers by Design Collective. The development, by Tower Companies, commissioned Design Collective to complete the first phase of the redevelopment by designing the 14-story mixed-use high-rise building that features, “…284 units, 177 parking spaces, and 30,000 square feet of indoor/outdoor amenity spaces including a two-story floating wellness center in the courtyard and a rooftop terrace overlooking Rock Creek Park,” Design Collective describes.

The primary phase of the redevelopment has already achieved a LEED Gold certification and is a beautiful example of shared wall space, utilizing a variety of exterior cladding materials.

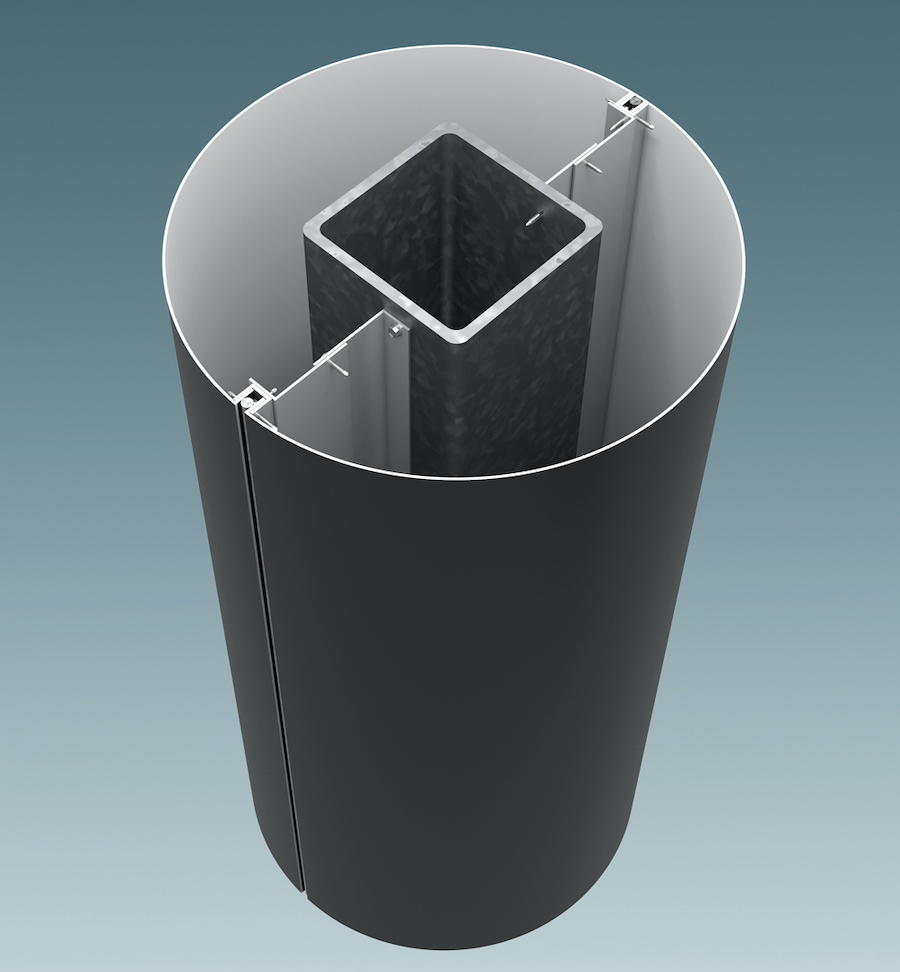

CEI Materials worked closely with the general contractors at Clark Construction Group to fabricate the building’s Reynobond and Alucoil metal components utilizing the customized R4000 Drained Rear-Ventilated Rainscreen System. The 4mm Reynobond, with a fire-retardant core, in Pewter and Platinum finishes is featured on the window mullions, soffits, column covers, and between masonry.

The Alucoil 4mm FR in a Corten Steel finish is featured on the building’s floating wellness center. The impressive center also utilizes a green roof with solar panels, furthering the sustainable nature of the redevelopment.

Totaling 17,500 SF of fabricated MCM, CEI Materials overcame a series of challenges in the design and installation of the metal components. CEI Project Manager, Garrett Harris, describes, “In the design phase, it was challenging to tie in the various system depths as well as the alignment of window extrusions, taking into account the multiple small elevations of the project to ensure all areas were captured and accurate to guarantee clear direction for the on-site installers.”

He further describes, “On the installation side, we worked within a tight schedule and site access, not to mention that about 90% of the work was installed off a swing stage not a boom lift, making installation even more difficult.” Supreme Metal Solutions installed the nearly 18,000 SF of metal components with a team that specializes in complex installations.

The site offers large open areas to encourage resident social spaces and community. The development is beautiful with intricate masonry coupled with various metal components featured throughout. The different exterior materials create a versatile design that reflects and refracts natural and artificial light offering a unique viewpoint at every angle.

.png)