News

Make CEI Materials the Basis of Your Design

Contact Your Closest Rep“Greatness can only be achieved with Commitment, Enthusiasm, and Integrity.”

.png)

Work With Us

The contents of this webpage are Copyright © 2025 CEI Materials. All Rights Reserved.

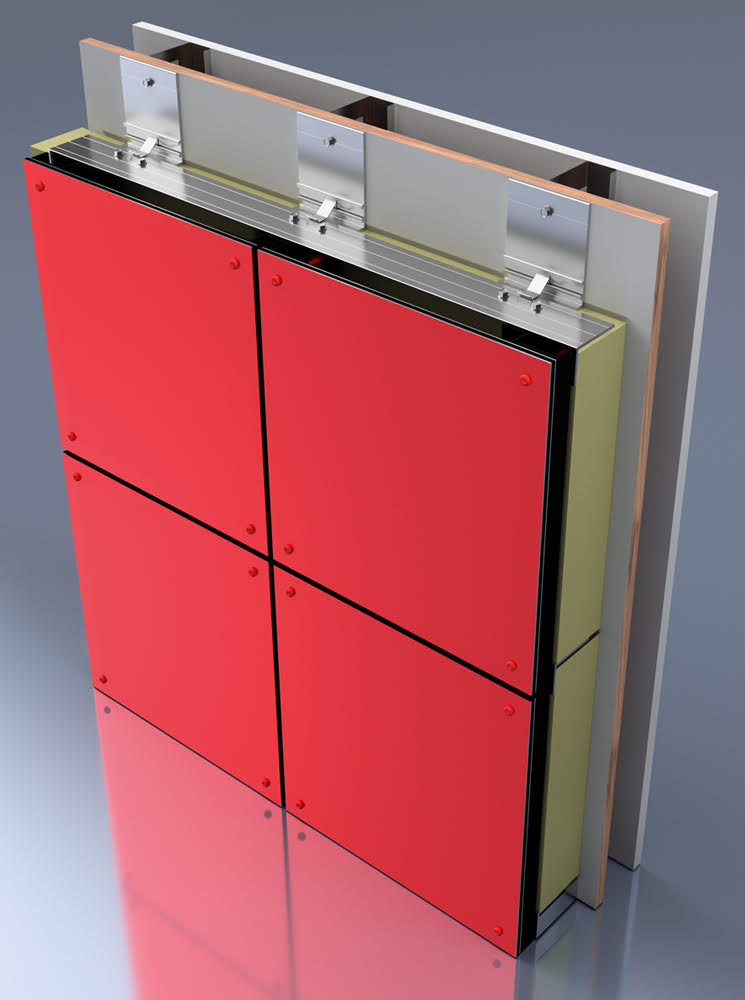

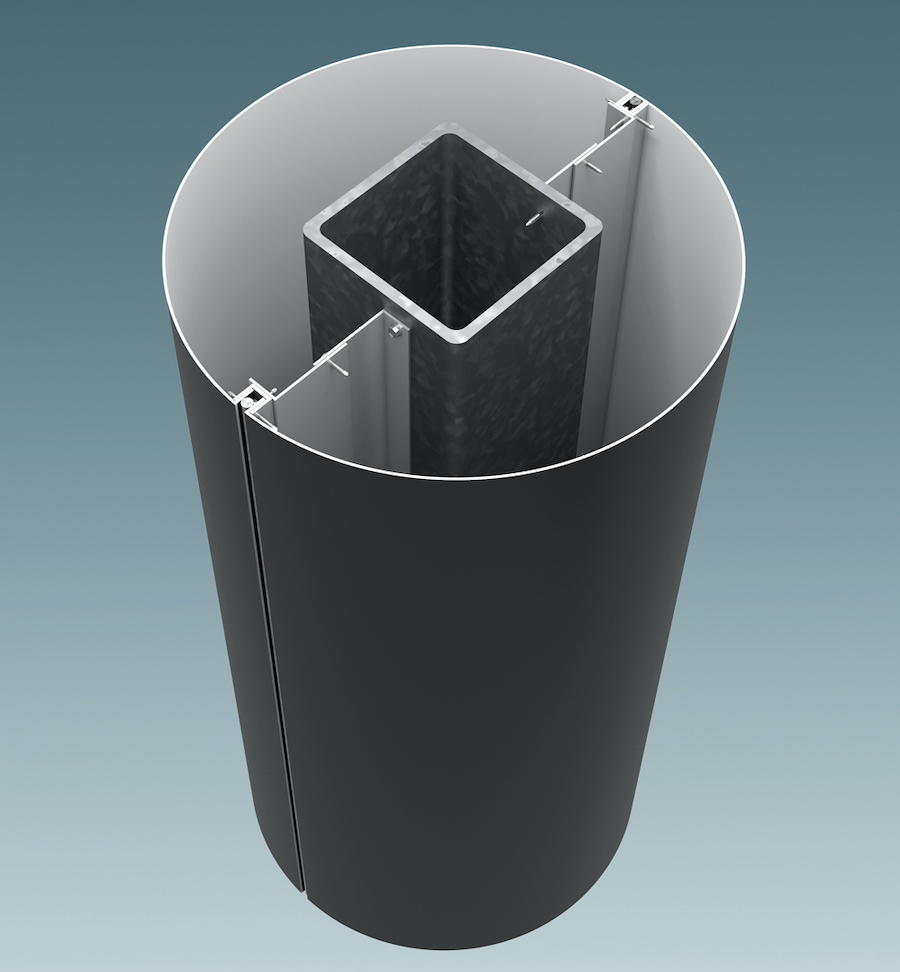

Specialties: Aluminum Composite Materials, Aluminum Composite Fabricator, Aluminum Composite Panels, Aluminum Panels, Architectural Metal, Metal Composite Materials, Metal Panels, Phenolic Panels, Architectural Panels, Composite Panel Fabricator, Architectural Canopies, Louvers, Sunshades, Composite Panel Manufacturer, Column Covers