Architects Design Headquarters Extension With The Help Of CEI Fabricated Metal Systems

| Project Name: | Sandvik Coromant NJ Headquarters |

| Location: | Fair Lawn, NJ |

| Architect: | NK Architects |

| General Contractor: | Structure Tone |

| Installer: | Supreme Metal Solutions |

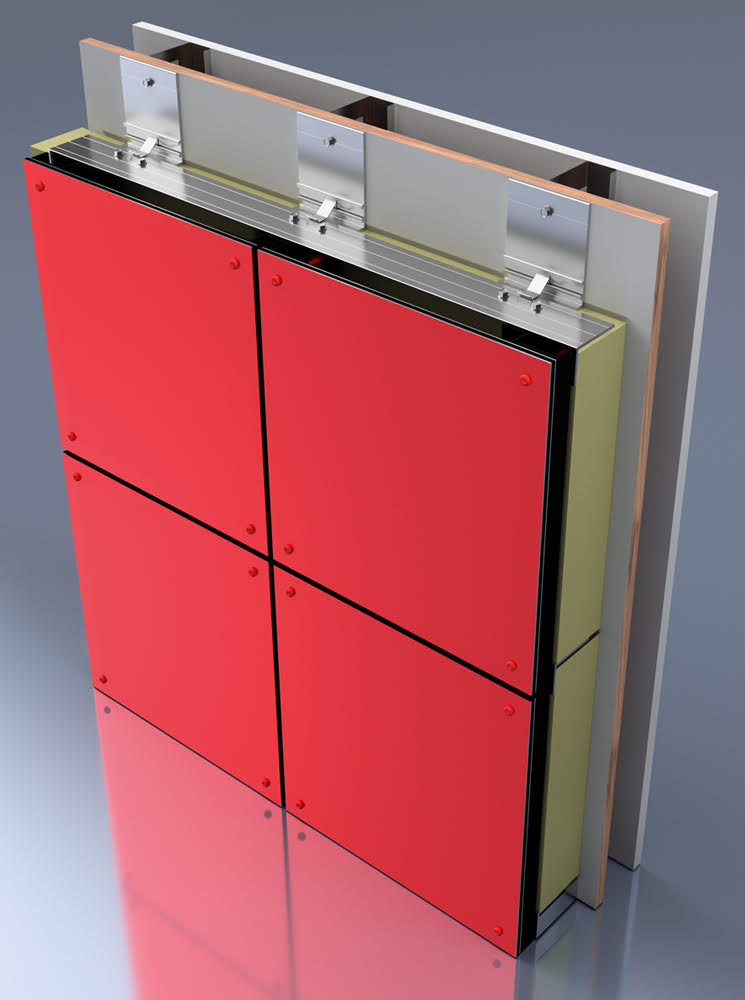

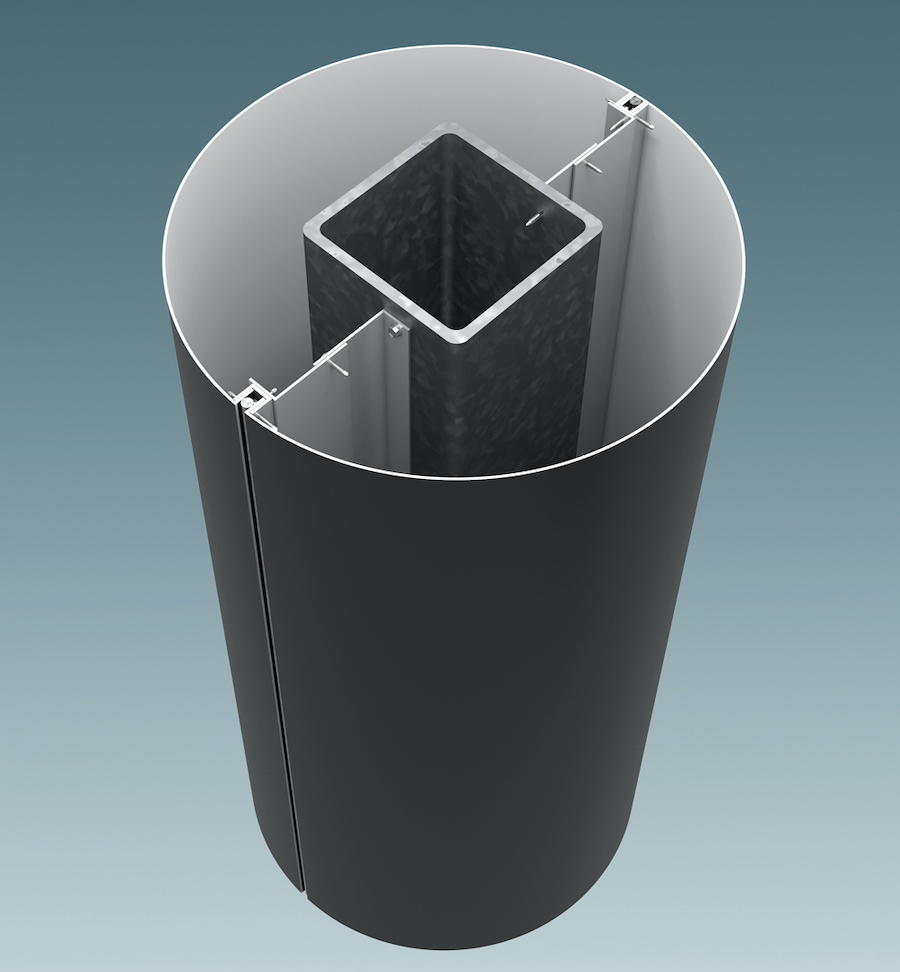

| CEI Materials System: | W5000 |

| Products: | MCM, Single Skin, Soffit, Louvers, Screen Walls, Prefinished Metal Coping |

| Photography: | NK Architects |

Sandvik Coromant was founded in 1862 as the first manufacturer of steel utilizing the Bessemer process, a method utilized to inexpensively mass-produce steel developed in 1856. The Swedish company began making cemented carbide tools in the 1940s and soon became a leader in the metal cutting industry branching into a wide range of industries from biotechnology to defense and aerospace.

The company’s North American corporate campus was built in the 1950s and the 10-acre space was in need of updating. The company commissioned NK Architects to develop a master plan for the space that would showcase the company’s movement into the 21st century.

©NK Architects

The designers at NK Architects, led by principal architect Allen R. Kopelson describe, “The scheme that was developed included the renovation of a single-story manufacturing building, raising the roof of another manufacturing building to insert a second floor for office space and the demolition of the existing headquarters office building. The renovated structure has a new energy efficient exterior skin, windows and mechanical system.”

©NK Architects

With a heavy focus on innovation, the architects designed the interior with the purpose of creating a well-lit, well-designed, communicative environment for employees. For this, they designed the interior to resemble what they call streets, with a “main street” and “secondary streets” that lead away from the centralized space where a large atrium exists. The “main street” runs from the entrance through the back of the building, while the secondary streets bisect it to lead employees and visitors to other centralized locations like the dining area.

The administration at Sandvik believes that their employees do best in an environment where they have open communication with others to discuss upcoming projects. “This is especially desirable after spending years in small departmental suites where the experience of a chance encounter to discuss a current project or issue was nonexistent,” the architects explain.

©NK Architects

The project utilized a wide range of materials, allowing CEI Materials to showcase their expertise in metal fabrication and custom system solutions. The structure features 4,750 square feet of Reynobond MCM and over 20,000 square feet of Single Skin materials including Fabral panels, MBCI Soffit panels, Architectural Screen Walls and Louvers and prefinished metal coping. The metal materials were fabricated using CEI’s W5000 Series, a Route and Return Silicone Joint System.

With such a large corporate campus to work around, Project Manager and CEO of CEI Materials, Jeff Henry describes, “As the project was an addition to an existing building that remained occupied during construction, with multiple phases, we needed to work closely with the team on scheduling and logistics.”

©NK Architects

Aside from the tight lead-time there were several different types of metal panel interfaces that required special detailing to ensure a clean weather tight finish. Additionally, the louvers on the Southwest corner of the building were custom fabricated by CEI and flown into place by crane. Lastly, CEI worked closely with the general contractors at Structure Tone and the installers at Supreme Metal Solutions to adhere to the building’s occupancy schedule. For example, the attachment brackets mounted to the masonry were drilled and installed after hours.

©NK Architects

The architects were purposeful in their design to allow portions of the building to remain unaltered, describing, “The existing structure of the buildings has been left exposed where possible to maintain a sense of the historical context of the manufacturing history that occurred on the site for fifty years.”

all information and photography courtesy of NK Architects

.png)