Blog originally published on November 18, 2016. Updated on February 7, 2025.

Cladding is a term given to an outer layer that is bonded to a core, or inner layer. Metal cladding is specifically used to describe a metal outer layer—cladding—that is bonded to a core metal material. The outer and inner metals are typically dissimilar.

The process of metal cladding is done within the industry of metallurgy. Metal cladding involves heating the various metals up to very high temperatures, pouring them into molds, and then allowing them to cool down. There are additional chemicals mixed with the metals in order to ensure an unbreakable chemical bond. Because of the specialized process and equipment needed to clad metal, it is almost solely done in specialized metallurgy plants by skilled tradesmen, or with dedicated robotic equipment.

Metal cladding is used extensively in manufacturing because of the potential for cost savings. For example, the U.S. Mint utilizes a metal cladding process to manufacture coins. Dimes, quarters, half-dollars, and dollar coins are all clad. The core and cladding of these coins range from manganese brass, copper, alloy metals, nickel, and zinc, while the cladding on the outsides may be copper, nickel, or a mixture of metals called an "alloy." When certain metals are scarce or more costly to obtain, metal cladding makes it possible to use a much lower percentage of that metal by bonding it to a plentiful, less expensive metal.

In addition to coins, metal cladding can be seen in everyday items such as non-stick cookware, stainless steel cookware, locks, automobile parts, and other metal products or metal trim. But how can metal cladding be a game-changer for your next construction project? Let's find out!

Understanding Metal Cladding: Definition and Purpose

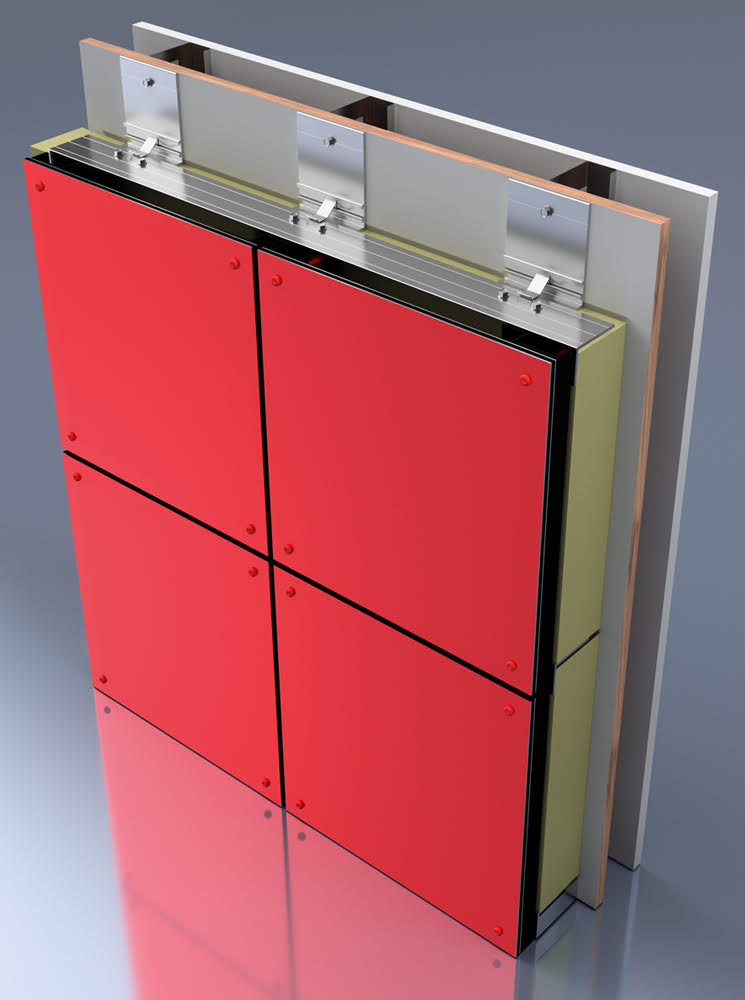

Metal cladding is a non-loadbearing layer attached to the exterior of a building, serving multiple purposes, including protection, aesthetics, and functionality. The primary purpose of metal cladding is to provide a protective outer layer that shields the building from harsh weather conditions, such as rain, wind, and UV rays. This protective barrier not only enhances the building’s durability but also contributes to its visual appeal, offering a sleek and modern look. Additionally, metal cladding plays a crucial role in improving the building’s energy efficiency by providing an extra layer of insulation, which helps in maintaining a stable indoor temperature.

Enhancing The Architectural Appeal of Your Building with Metal Panels

Metal cladding is also used in construction materials for many commercial and industrial buildings, often in the form of cladding panels. In this case, the metal exterior may be bonded to a non-metal core. High performance metal cladding in construction is used for cost savings, but also to enhance the functionality of the façade. A metal-cladded roof or siding will protect against rain, while the core, possibly foam core, provides insulation properties. Additionally, metal cladding plays a crucial role in improving the building’s energy efficiency by providing an extra layer of insulation, which helps in maintaining a stable indoor temperature. Metal panels are also available in a variety of colors to give your building a unique look and align with brand identity.

Stylish, durable, and efficient, a metal wall panel is a great fit for commercial construction. Plus, if changes or repairs are needed later on down the line, it's easy to configure and replace (unlike traditional roofing materials!)

Architectural metal panels have many of the same benefits as metal roofing systems, such as:

- Easy installation

- Heat and cold weather insulation

- Fire resistant

- Prevent rain and moisture accumulation

- Protects against mold, erosion, and other common structural integrity breaches

The installation process of metal cladding is straightforward, involving systematic steps to ensure proper attachment and weather tightness. That’s right: when properly installed, metal wall panels can even help you lower those summer cooling bills!

Benefits of Metal Cladding

Metal cladding offers numerous benefits that make it a popular choice for modern construction:

-

Protection from Harsh Weather Conditions: Metal cladding acts as a shield against rain, wind, and UV rays, reducing the risk of damage to the building’s structure and interior.

-

Enhanced Aesthetic Appeal: With a wide range of design options and flexibility, metal cladding allows for creative architectural expressions, enhancing the overall look of the building.

-

Improved Energy Efficiency: By reducing heat loss in the winter and keeping the building cooler in the summer, metal cladding helps in lowering energy consumption and costs.

-

Increased Durability: Metal cladding is known for its ability to withstand harsh weather conditions and requires minimal maintenance, ensuring long-term performance.

-

Fire Resistance: Many metal cladding materials meet local building codes and regulations for fire resistance, providing an added layer of safety.

-

Insulation Properties: Metal cladding systems often include insulation layers that enhance the building’s thermal performance, contributing to energy savings.

-

Sustainability: Many metal cladding materials are recyclable and environmentally friendly, making them a sustainable choice for construction projects.

Types of Metal Wall Panels

CEI Materials architectural cladding solutions include:

- CLADLOK™ Modular Metal Panels

- HPL Panels

- MCM Panels

- Back Pans & Infill Panels

- Aluminum Plate Panels

- Louvers & Sunshades

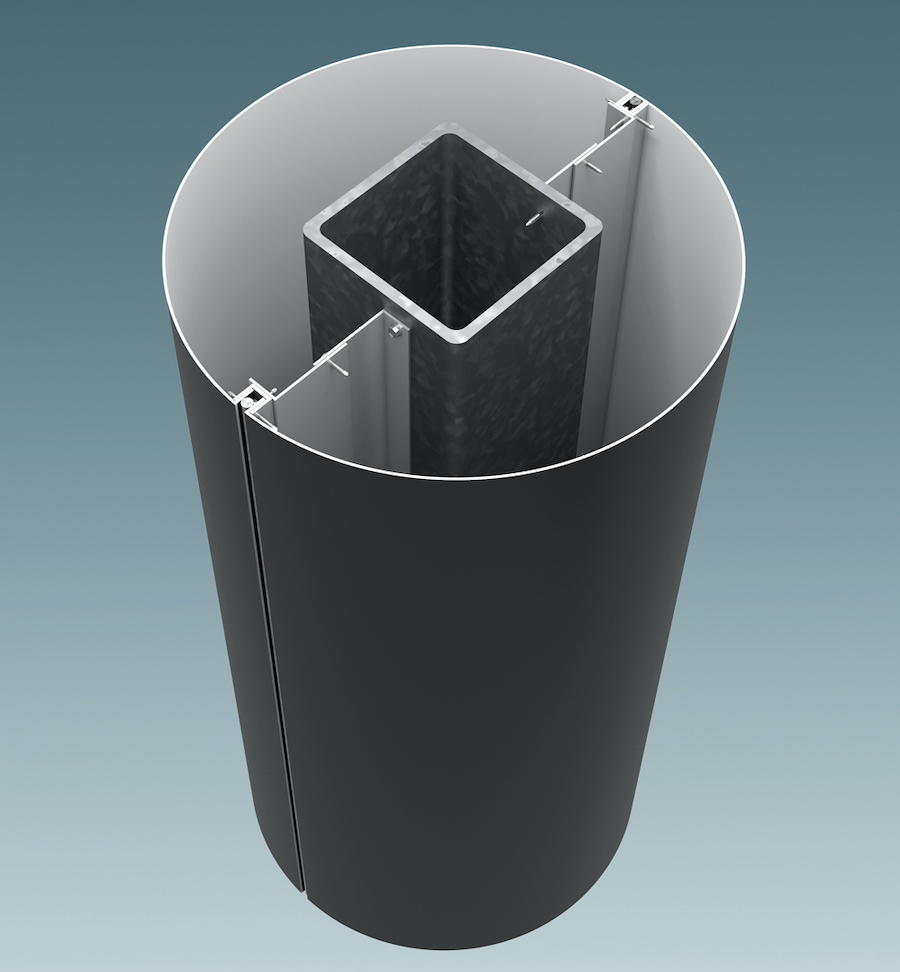

- Wet Joint, Dry Joint, & Hairline Joint Column Covers

Composite panels are also a popular choice, offering durability and cost-effectiveness for various architectural applications.

Materials Used in Metal Cladding

Metal cladding encompasses a variety of materials, each offering unique advantages:

-

Aluminum: Known for its corrosion resistance, durability, and aesthetic appeal, aluminum is a popular choice for metal cladding.

-

Steel: Offering strength, durability, and affordability, steel is widely used in metal cladding applications.

-

Copper: Valued for its unique aesthetic appeal and excellent corrosion resistance, copper adds a distinctive look to buildings.

-

Zinc: Providing a durable and corrosion-resistant option, zinc is often used in metal cladding for its longevity.

-

Titanium: With a high strength-to-weight ratio and excellent corrosion resistance, titanium is ideal for high-performance cladding systems.

-

Stainless Steel: Known for its excellent corrosion resistance and durability, stainless steel is a reliable choice for metal cladding.

-

Brass: Offering a unique aesthetic appeal and excellent corrosion resistance, brass is used in specialized cladding applications.

Metal Cladding: Finishes and Coatings

Finishes and coatings play a crucial role in enhancing both the aesthetics and performance of metal cladding systems. Common finishes and coatings include:

-

Powder Coating: Provides a durable and corrosion-resistant finish, available in a wide range of colors.

-

Anodizing: Offers a durable and corrosion-resistant finish, enhancing the natural beauty of the metal.

-

PVDF Coating: Known for its durability and resistance to weathering, PVDF coating is a popular choice for metal cladding.

-

Polyester Coating: Provides a durable and corrosion-resistant finish, suitable for various environmental conditions.

-

Acrylic Coating: Offers a durable and corrosion-resistant finish, often used for its aesthetic versatility.

-

Ceramic Coating: Provides a durable and corrosion-resistant finish, known for its high-performance properties.

By selecting the appropriate finishes and coatings, architects and builders can ensure that metal cladding systems not only look great but also perform exceptionally well in protecting the building.

Contact CEI Materials for Architectural Metal Wall Panels

If you're looking for metal cladding fabrication services or commercial construction services, contact CEI Materials today. Since 2008, we've been a trusted metal cladding fabricator throughout the United States. As standout specialists in retail, commercial, and corporate identity solutions and building exteriors, we’ve completed over 1,000 projects with sleek, durable systems and surfaces.

We are your full-service fabricator for architectural wall panels, delivering results on time and within budget. We believe in fostering open communication between architects, building owners, contractors, manufacturers, and fabricators. All systems at CEI Materials are tested to ASTM and AAMA standards and are NFPA 285 compliant. With in-house engineering and thorough quality assurance processes, you can rest assured your new cladding system is up to code.

Make CEI Materials the basis of your next project. To see more of our inventive facade solutions, browse our portfolio. To discuss partnering with us on new and retrofit construction projects, request a quote today.

.png)