Blog updated on February 7, 2025.

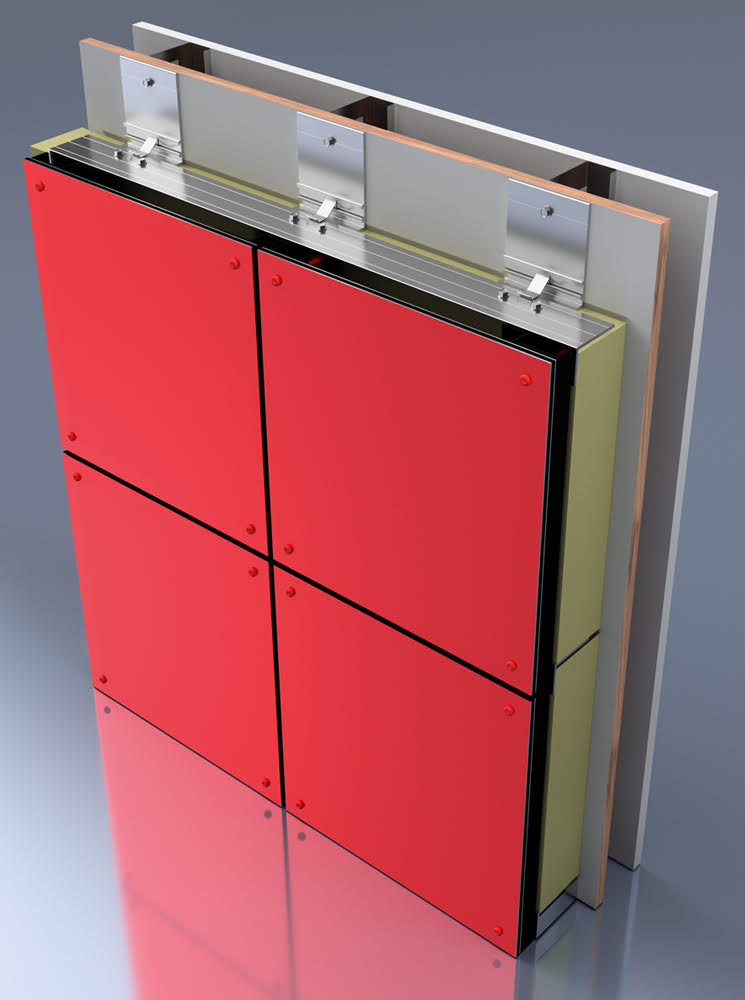

Aluminum Composite Panels, also known as aluminum composite panel, represent a prevalent building material with diverse applications in both construction and signage. Comprising two thin, flat aluminum panels adhered to a non-aluminum center, this material often goes unnoticed in our daily lives. Despite its inconspicuous presence, aluminum composite panels offer intriguing facets that may not be widely known. Here are 12 noteworthy facts shedding light on the versatility and benefits of aluminum composite panels.

Extensive Color Options

Aluminum composite panels boast a palette of nearly 40 different colors, with the added flexibility of customization to suit specific building applications. Designers can emulate the appearance of aluminum, copper, zinc, or stainless steel, providing unparalleled design versatility characterized by clean and modern lines that endure the test of time. Featuring a solid polyethylene core, these panels offer enhanced performance and durability compared to traditional materials like MDO and solid aluminum panels. This diversity makes aluminum composite panels a unique choice, challenging to match in terms of aesthetic adaptability.

Remarkable Lightweight Characteristics

Following a complete installation, the finished weight of an aluminum composite panel averages a mere 2.5 pounds per square foot. This remarkable lightweight attribute coexists with exceptional durability and longevity, distinguishing it from alternative materials. The combination of structural resilience and reduced weight contributes to the practicality and ease of handling during the installation process. Additionally, aluminum composite panels are widely used in architectural cladding, offering versatility in design for façades and various interior design elements.

Environmental Sustainability

Opting for construction with aluminium composite panels aligns with environmental responsibility, given that these panels are considered sustainable building materials. Typically crafted from approximately 85% recycled aluminum, these panels contribute to reducing environmental impact. Moreover, certain states may offer tax credits for such eco-friendly choices, while LEED credits from the U.S. Green Building Council may be attainable for buildings voluntarily incorporating aluminium composite panels. This underscores the commitment to sustainable construction practices.

Fire Resistance Compliance

Addressing global building codes, aluminum composite panels are available with cores composed of fire-resistant materials. Specifically engineered to meet stringent codes applicable to large structures such as skyscrapers and high-rise buildings, these panels ensure high resistance to fire, enhancing their durability and safety. Prospective buyers should scrutinize the fire specifications of specific aluminum composite panels to ascertain compliance with their state’s code requirements, emphasizing safety in building applications.

Extreme Temperature Resistance

ACPs are built to withstand the elements. They maintain their structural integrity in temperatures ranging from -50°C to +80°C, making them ideal for climates that experience extreme heat or freezing conditions. Whether it’s the scorching desert sun or icy alpine environments, ACPs resist warping, cracking, or degrading, ensuring long-term durability. This temperature resistance also makes them energy efficient, as they help maintain consistent indoor temperatures, reducing the need for excessive heating or cooling.

Superior Thermal & Acoustic Insulation

Beyond aesthetics, ACPs contribute to building efficiency. Their layered design offers excellent thermal insulation, reducing heat transfer and helping to maintain indoor temperatures. This can lead to lower energy costs for heating and cooling. Additionally, ACPs provide acoustic insulation, reducing external noise—perfect for urban environments where sound control is essential.

Aluminum composite panels are also widely used in ventilated facades, which enhance the building's modern and functional aesthetics while contributing to energy efficiency by serving as insulation and facilitating air circulation.

Non-Toxic & Safe for Indoor Use

ACPs are specially designed and manufactured under strict environmental and health safety standards. Unlike some traditional materials, they are lead-free and use VOC-free paints, meaning they don’t release harmful chemicals into the air. This makes them a safe choice for both exterior and interior applications, including healthcare facilities, schools, and residential buildings.

Flexible Design & Customization

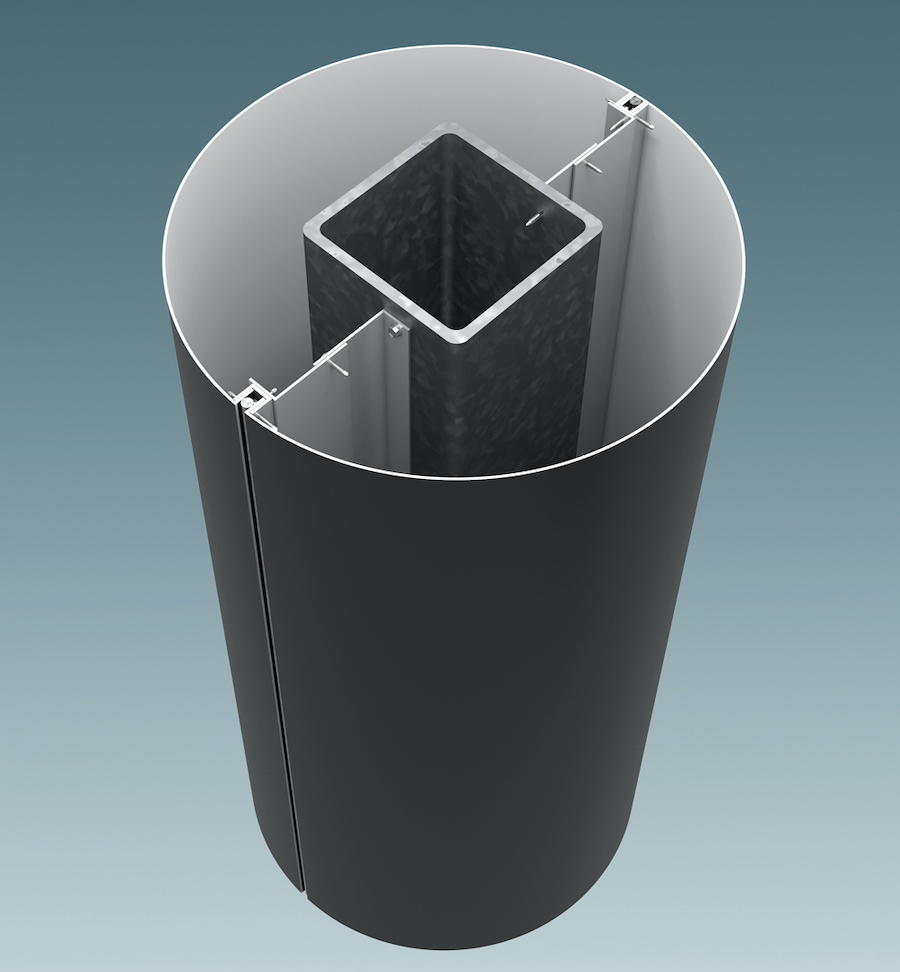

One of the standout features of aluminum composite material (ACM) is its flexibility—literally. They can be easily bent, folded, or shaped into complex forms like curves, domes, and geometric patterns without compromising strength. This versatility gives architects the freedom to push creative boundaries, designing façades and interiors that are both functional and visually striking.

Lightweight, Yet Structurally Strong

While we’ve mentioned ACPs’ lightweight nature, what’s remarkable is how that lightness pairs with high structural strength. Despite being lighter than many traditional materials, ACPs offer exceptional rigidity and impact resistance. This strength-to-weight ratio makes them ideal for high-rise buildings, where reducing structural load is critical without sacrificing durability. Additionally, aluminum composite panels often exhibit superior strength when compared to other metals, making them a versatile choice for various construction and architectural applications.

Iconic Structures That Showcase Aluminum Composite Panels

From the VanDusen Botanical Garden in Canada to Spaceship Earth at Disney’s Epcot, ACPs have been used in architectural landmarks around the world. Their adaptability to different design styles—from ultra-modern to classic—proves their versatility. ACPs not only provide structural benefits but also play a key role in defining a building’s aesthetic identity. Additionally, aluminum composite panels offer significant advantages over traditional materials like natural stone in terms of weight, maintenance, and energy efficiency.

HVAC Efficiency Boosters

ACPs do more than insulate—they can enhance the performance of a building’s HVAC systems. By reducing thermal bridging (where heat escapes through the building envelope), ACPs help maintain consistent indoor temperatures. This efficiency reduces the workload on heating and cooling systems, leading to lower energy consumption and cost savings over time.

Easy Maintenance for Long-Term Value

Unlike some cladding materials that require frequent upkeep, aluminium composite panels (ACPs) are low-maintenance. They resist stains, corrosion, and environmental pollutants. A simple cleaning routine with mild soap and water is usually enough to keep them looking fresh and new. Their durability and minimal maintenance requirements make ACPs a cost-effective choice over the life of a building.

Regulations and Compliance

Aluminum composite panels must comply with various building regulations and codes, including those related to fire safety, thermal and acoustic insulation, and energy efficiency. Manufacturers of aluminum composite panels must obtain country-specific building certifications and ensure that their products meet the required standards.

In terms of fire safety, aluminum composite panels can be non-flammable or non-combustible, depending on the type of core used. The panels must also meet the requirements for thermal and acoustic insulation, as well as energy efficiency.

It is essential to ensure that the aluminum composite panels used in a project comply with the relevant building regulations and codes to ensure safety, sustainability, and energy efficiency.

In the realm of construction, integrating Aluminum Composite Panels requires meticulous attention to detail. BIM Model Coordination, incorporating these panels seamlessly into Building Information Modeling (BIM), enhances the precision of design and construction processes. Ensuring the accurate representation of aluminum composite panels within a BIM model facilitates effective collaboration among stakeholders, promoting a streamlined and efficient construction workflow. Thus, the integration of Aluminum Composite Panels into BIM Model Coordination enhances project accuracy and efficiency, reflecting a forward-thinking approach to modern construction practices.

.png)