Metal Composite Panels And The Role Of Fabricators In The Architectural Process

Metal composite materials, including aluminum composites, have been prominent in the architectural market since the 1970s. The materials have evolved to accommodate the ever-changing architectural space, pushing manufacturers to create more innovative product lines. These innovations have been seen in product finishes and even core construction, to produce more sustainable and fire-resistant technologies. Each of the major manufacturing players in metal composites have the ability to produce products that continue to please architects due to a variety of factors.

CEI Materials General Contractor/Architect Spotlight: PROCON, Inc

PROCON Inc. has nearly a century of construction expertise, the company has been privately owned for four generations. The award-winning firm out of Manchester, NH is unique in that they provide architecture, engineering and construction services. A true design-build firm, PROCON has completed projects across New England in a variety of applications.

What The Modern Fabricator Has To Offer The Architectural Community

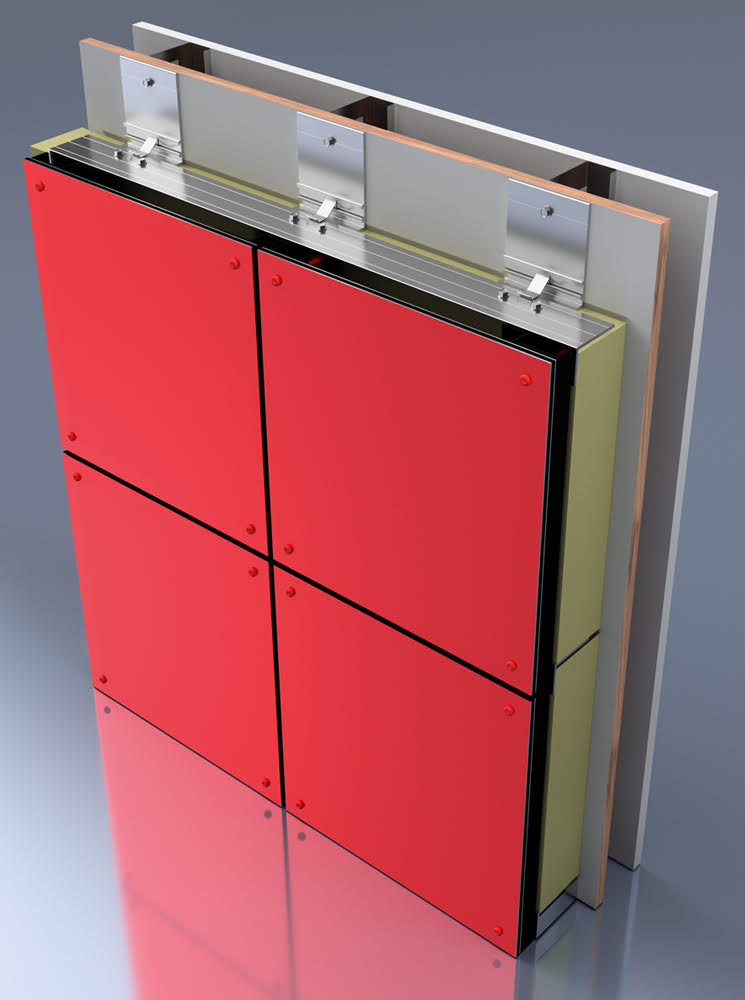

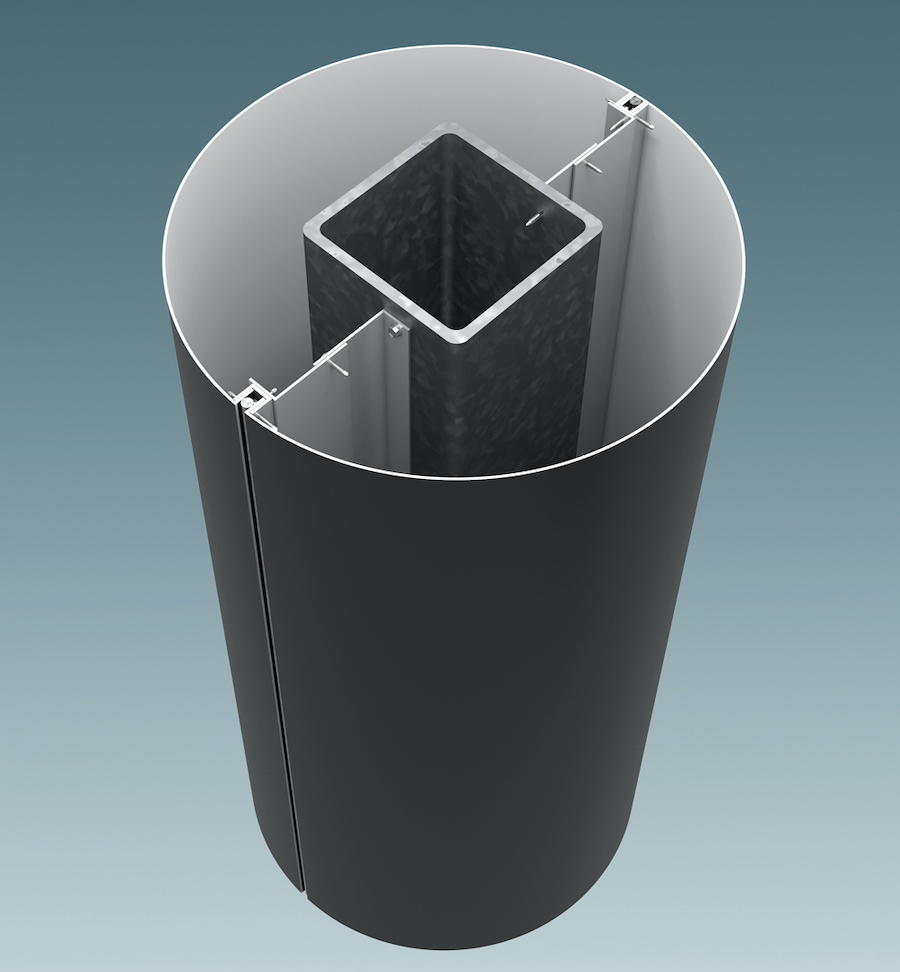

The modern fabricator provides a multitude of product offerings. The exterior cladding market is competitive, requiring fabricators to offer a variety of potential options for a façade. Each product should be tested, proven and offer a unique aesthetic quality. At CEI Materials we offer the architectural community metal composite panels, plate panels, modular panel systems, high pressure laminate (HPL) and modular services.

CEI Materials General Contractor Spotlight: Dellbrook/JKS

Dellbrook|JKS has over three decades in the construction industry. As one of the largest and fastest growing construction companies in the Northeast, the powerhouse company has produced a variety of impressive buildings in various markets. As the team at Dellbrook describes, “Our collaborative, long-standing relationships with the Northeast’s most qualified subcontractors means we effectively deliver a quality project on time and on budget with minimal disruption to ongoing operations. Whether it is a large commercial project or a high-end residential remodel, our projects maintain cooperative and team-driven spirit fueled by our firm’s philosophy and management style.”

The 3 Greatest Benefits Of Using A Perforated Metal Product

There are a whole host of benefits to the utilization of perforated metal. Its advantageous nature allows for architects to use the material based solely on a variety of factors including its obvious aesthetic qualities or its sustainable attributes. Architects and designers are continuously searching for products that provide an unusual aesthetic without sacrificing durability, strength or sustainable design. Here we explore what we consider the three greatest benefits of using a perforated metal product.

.png)